The G750 5-Axis machining centre offers our customers industry best manufacturing of large milled parts and will be part of a 3 machine FMS work cell. This latest addition to our capabilities has 47.2” x 47.2” x 26.5” work travel and 30,000 RPM spindle speed.

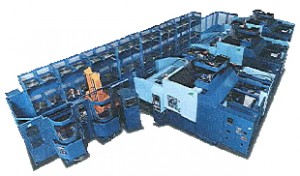

Matsuura MX-330 PC10

Royell has added a second Matsuura MX-330 PC10 to its shop floor automation for the production of smaller complex parts. This new 5-Axis machining centre will support the increase in our customers aircraft production rates.

High Speed extrusion machining with our latest Chiron FZ 15 MP with Berns automatic extrusion loader.

Multifunctional machining center for the complete machining of workpieces of different lengths from extruded profiles of any type. Milling, drilling, threading, countersinking, reaming or separating – anything is possible, regardless of whether series parts or variants are being machined.