The addition of a RoboDrill machining cell will enable parts to be conveyor fed both in and out of the machining station for unattended production. This is another step toward full automation of aircraft interiors parts manufacturing process that will enable Royell to drive down costs. Less handling and increasing throughput to help meet cost competitive requirements in this global …

ROYELL ADDS TURN/MILLING CAPABILITY TO SUPPORT 787 DOOR PROGRAM

Royell has added a Doosan Puma 2100SY turn centre with milling in the Y axis. This machine comes with a full C axis sub-spindle and a bar feeder.

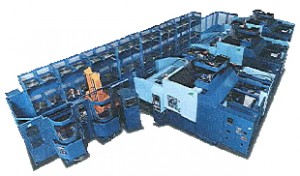

FINAL PHASE OF NEW 5-AXIS FLEXIBLE MANUFACTURING SYSTEM INSTALLED

Royell has successfully installed the fourth and final phase of it’s new 5-Axis Flexible Manufacturing System. The completed aluminum machining cell configuration consists of 4 CNC machines tied together by a 44 pallet system that feed material 24 hours a day with minimal supervision. This is a further step toward manufacturing automation that is gradually replacing the more conventional stand …