Royell has acquired 3 additional Robodrill T-21iFa mills. Eventually destined for full automation, these machines will be used to fill short-term capacity gaps and for process development work.

Assembly and Shipping; Here we grow again!

Royell has opened a new Assembly, Kit Integration, and Shipping building on campus. The new facility resides in a building acquired and expanded specifically for this purpose, allowing wide open shipping and receiving lanes and a logical process flow. The move provides room for additional machining operations within the main plant.

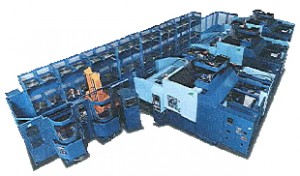

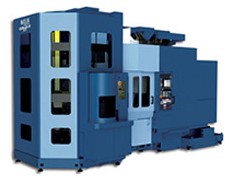

NEW 5-AXIS MULTI-TASKING MANUFACTURING SYSTEM

Milling, turning and grinding on the same machine platform all coupled with 5 axis unmanned performance. Royell’s latest acquisition in automation is a Matsuura Cublex-35 which features 35 pallet stations. This equipment offers the ability to not only mill and turn but also grind to high tolerance with 5-Axis 20,000 rpm milling and a 3000 rpm C-Axis turning feature. The primary focus will be to support close tolerance passenger door components machined from titanium and stainless steel.

Milling, turning and grinding on the same machine platform all coupled with 5 axis unmanned performance. Royell’s latest acquisition in automation is a Matsuura Cublex-35 which features 35 pallet stations. This equipment offers the ability to not only mill and turn but also grind to high tolerance with 5-Axis 20,000 rpm milling and a 3000 rpm C-Axis turning feature. The primary focus will be to support close tolerance passenger door components machined from titanium and stainless steel.