Royell has added a Doosan Puma 2100SY turn centre with milling in the Y axis. This machine comes with a full C axis sub-spindle and a bar feeder.

Royell has added a Doosan Puma 2100SY turn centre with milling in the Y axis. This machine comes with a full C axis sub-spindle and a bar feeder.

Daniela Escorcia Uncategorized

Chief Financial Officer

Joe is a Certified Public Accountant with over 20 years of experience in the accounting industry. As Controller, his responsibilities include supervision of daily accounting processes, managing cash flow, and preparing and analyzing financial information. Joe is especially interested in reducing costs and increasing productivity. He graduated from Central Washington University where he majored in Business Administration and Finance.

Site Manager, Assembly & Shipping Facility

Since joining the Royell team in 2000, Tom has filled a number of roles critical to the company’s development; Trainer and Organizational Development specialist is support of our Supplier Certification, Lean Manufacturing and Safety initiatives; Production Manager, helping bring standardized processes to our shop floor that set the ground work for our current Manufacturing System; Manufacturing Engineer and New Part Project Manager, which lead to his role as Manufacturing Engineering Manager where he pulled Manufacturing Planners, CNC Programming, Tool Design, and Tool Fabrication into a single department supporting new part implementation and stabilization of existing work.

Tom’s current role at Royell is Facilities and Maintenance Management, including project management for new site and equipment development and installation.

Tom came to Royell from Boeing Commercial Airplanes in Everett. He was involved in factory management, training development and delivery, and Boeing’s Lean Manufacturing activities, participating in major projects in the 747 factory and managing projects in the 777 factory. His efforts produced savings in standards and material costs and established a complete point of use delivery and replenishment system for assembly mechanics.

Operations Manager

Chris holds a degree in Industrial Technology from Washington State University. He worked for over 12 years at the Boeing Company. Chris brings to our team extensive lean manufacturing and production experience. He served in many leadership roles; as project manager, manufacturing engineering supervisor, shop supervisor, and lean manufacturing implementation manager. His leadership will greatly enhance our abilities to implement lean and expand our production capabilities.

Quality Manager

Steve is a graduate of Cleveland Institute of Electronics. He has spent approximately over 25 years in Quality Engineering, Management, and Consulting. He has managed, developed and implemented ISO 9000, QS 9000 and AS9100 based quality systems in the electronics, silicone rubber, composites and metallic industries. Responsibilities include directing the activities of the inspection, quality engineering, vendor assessment and risk evaluation and cost of quality metrics.

President & General Manager

Jamie is a college graduate of Washington State University. He is second generation in a family owned business, with over 25 years of experience in the aerospace industry. Responsibilities include strategic planning, cost and expense policies, financing, organizational and management development. Jamie believes in management by objectives and has worked diligently to form an experienced, dedicated, proactive management team to achieve the company’s strategic initiatives.

Int’l Sales & Business Development

Royell uses the services of Associated Technologies, for international sales and businesses development.

As an Apprenticed toolmaker and graduating from the UK in mechanical engineering, Robin started his aerospace career building tooling on the prototype A300 Airbus wing program. Working under Contract in Canada, Robin designed and built tooling for an aircraft modification program and developed a training program in aircraft structures and assembly. Robin has held positions including Production Manager and Marketing Director and has owned and operated a Boeing and Bell approved CNC machine shop which was recipient of a Canadian Export Award.

Associated Technologies has developed Royell’s international customer base in Canada, Asia and Europe.

[wp-svg-icons icon=”calendar” wrap=”i”] Feb 24, 2006

This Starrag 800X is the first of a 3 machine FMS that will add more world class capability to our ability to machine aluminum structural components. The new Starrag 800X with 120-kW spindle cuts medium-sized aluminum components up 57 inches or 1450 mm and offers up to 10 per cent increases in throughput via reduced machining times, with a reported 20 per cent savings in energy costs and up to 10 per cent savings in service and tool costs.

[wp-svg-icons icon=”calendar” wrap=”i”] Apr 18, 2016

[wp-svg-icons icon=”calendar” wrap=”i”] Apr 18, 2016

Royell has invested in the Kitamura HX630G technology. This heavy duty machining centre complete with a fastems 32 pallet linear system is the first of a three machine 4 & 5 axis hard metal and titanium cutting cell capable of machining parts up to 40 inches (1000mm)

[wp-svg-icons icon=”calendar” wrap=”i”] Dec 1, 2004

[wp-svg-icons icon=”calendar” wrap=”i”] Dec 1, 2004

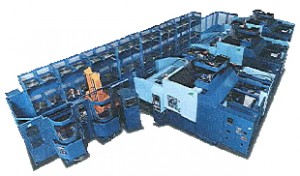

What started as a single machining cell brings in total to four machines of the exact same make, type and size. This manufacturing cell is used primarily for the production of a family of aluminum parts. This additional capacity allows for redundancy and added customer satisfaction that we are prepared for program growth as the industry .

[wp-svg-icons icon=”calendar” wrap=”i”] Jan 1, 2005

Royell has increased its inhouse capability to support their customers by adding not only more fabrication equipment but more importantly skilled personnel. With the addition of extrusion Hot Joggling, Stretching, Shrinking and Straightening capability Royell has also hired one of the best people in Mark Teeters to handle these activities on the shopfloor.

[wp-svg-icons icon=”calendar” wrap=”i”] Nov 21, 2005

[wp-svg-icons icon=”calendar” wrap=”i”] Nov 21, 2005

Royell is adding 10,000 sq ft of additional floor space to meet customer requirements and the continual growth in sheet metal fabrication and assembly.

“Our direction to develop our integration capabilities to support our customers growing supplier management and product integration needs has resulted in this shop floor expansion” says Jamie Yelle President and General Manager.

In the last 12 months Royell has grown not only its machining capability with the addition of (2) new high speed cells but also its sheet metal capability to support its spares and kitting requirements. This added floor space will enable further growth in these key areas of customer kitting and assembly.

[wp-svg-icons icon=”calendar” wrap=”i”] Feb 24, 2006

[wp-svg-icons icon=”calendar” wrap=”i”] Feb 24, 2006

Royell has added a further hard metal machining center to support its customers increasing build rates. This latest piece of equipment is a Mitsubishi M-H60D 4-Axis Horizontal Machining Center. This heavy duty machine has impressive accuracy and repeatability +/- .001 mm (0.00004″) will used primarily to support our customers titanium and stainless steel parts requirements.

[wp-svg-icons icon=”calendar” wrap=”i”] May 30, 2006

[wp-svg-icons icon=”calendar” wrap=”i”] May 30, 2006

Royell has added a further Kitamura high speed horizontal machining cell for medium sized parts manufacture. This super fast palletized machine is a simultaneous 4 Axis ultra precision machining center with spindle speeds up to 20,000 RPM and feed rates of 2,000 ipm. This equipment has been purchased to support the initial ramp up on a new multi year aircraft program.

[wp-svg-icons icon=”calendar” wrap=”i”] May 31, 2006

[wp-svg-icons icon=”calendar” wrap=”i”] May 31, 2006

Royell has increased machining capacity within the Spares and Aircraft Modification manufacturing business unit with the addition of a new CNC machining center for volume part run sizes.

HAAS VF-4 vertical machining center with a 10,000 rpm 40 taper spindle and 50 x 20 x 25 inch table travel for aluminum work.

Also adding (2) HAAS VF-3YT vertical

machining centers with 7,500 rpm 50 taper spindles and 40 x 26 x 25 inch table travel. These are compact machines with good rigidity for hard metal machining. One machine will be used to support titanium parts roughing before finishing on our FMS whilst the other will machine complete complex titanium and inconel fittings. Both these machines are fitted with full 4 axis capability.

[wp-svg-icons icon=”calendar” wrap=”i”] Oct 30, 2006

[wp-svg-icons icon=”calendar” wrap=”i”] Oct 30, 2006

To prepare the company for future growth and to maximize the flow pattern of administrative functionality our offices have been totally remodeled and expanded to 6000 sq ft.

The new look is an open concept design with many filing options removed from the work floor and wall mounted at convenient levels. The addition of two new conference rooms along with an updated training room complete with the latest digital equipment will support our long term plans. The final part of this 2006 expansion is an additional 2500 sq ft which will be the future center for our supply chain management activities.

[wp-svg-icons icon=”calendar” wrap=”i”] Nov 24, 2006

[wp-svg-icons icon=”calendar” wrap=”i”] Nov 24, 2006

We achieved a perfect score on our recent ISO9000:2000 + AS9100B audit! This was somewhat of a surprise to us since our team that works continually developing better and leaner systems believe that the best is yet to come. Over the last ten years we have implemented a lean enterprise that includes leading edge technologies on the shop floor such as wireless communications to achieve work cell visibility and parts tracking. We have also developed our own software applications that not only manage these tasks but is also web based to help manage our supply chain from anywhere with an Internet connection.

[wp-svg-icons icon=”calendar” wrap=”i”] Feb 5, 2007

[wp-svg-icons icon=”calendar” wrap=”i”] Feb 5, 2007

Over the last few months Royell has steadily increased its sheet metal capabilities to support spares, production and kitting requirements.

This capability includes a new Lawson 4-Post Hydro Form Press with a useful 320 Ton pressure which can form parts up to 18 inch x 40 inch. The Punch Press is a 60 Ton Bliss and will support production requirements.

[wp-svg-icons icon=”calendar” wrap=”i”] Feb 19, 2007

[wp-svg-icons icon=”calendar” wrap=”i”] Feb 19, 2007

We have installed the first of four horizontal CNC machines to support Boeing on the 787 program.

These machines will be installed in staged intervals as the airplane build rate grows and will form a dedicated manufacturing cell.

A family of titanium parts will be manufactured and delivered at the required frequency in kit form to support production.

[wp-svg-icons icon=”calendar” wrap=”i”] Aug 24, 2007

[wp-svg-icons icon=”calendar” wrap=”i”] Aug 24, 2007

This purchase will not only support our production shop floor with fast turn around cutter regrinds but will enable the manufacturing of new cutters including special profiles for difficult part machining.

Features include:

[wp-svg-icons icon=”calendar” wrap=”i”] Oct 29, 2007

Royell has repeated an achievement from last year and recorded another perfect score on the annual ISO9000:2000 + AS9100B audit! This is a testament to the continuous improvement and training that has become a way of life throughout the company. A job well done by all and keep up the excellent work.

[wp-svg-icons icon=”calendar” wrap=”i”] Nov 5, 2012

Milling, turning and grinding on the same machine platform all coupled with 5 axis unmanned performance. Royell’s latest acquisition in automation is a Matsuura Cublex-35 which features 35 pallet stations. This equipment offers the ability to not only mill and turn but also grind to high tolerance with 5-Axis 20,000 rpm milling and a 3000 rpm C-Axis turning feature. The primary focus will be to support close tolerance passenger door components machined from titanium and stainless steel.

[wp-svg-icons icon=”calendar” wrap=”i”] May 15, 2008

[wp-svg-icons icon=”calendar” wrap=”i”] May 15, 2008

Royell’s further facilities expansion will be completed this summer to house the installation of the latest in 5-axis machining technology and support equipment. This expansion will also free up an additional 7000 sq ft of floor space to increase assembly capability.

[wp-svg-icons icon=”calendar” wrap=”i”] Jul 15, 2008

[wp-svg-icons icon=”calendar” wrap=”i”] Jul 15, 2008

Royell is installing the first phase of its new 5-axis Manufacturing System. Once complete this multi-million dollar investment will consist of four Machining Centers three of which will be 5-axis Vertical and the fourth a 4-axis Horizontal.

The completed configuration will be tied together by a 44 pallet system to stock and feed material 24 hours a day. This system is designed to efficiently manufacture aluminum parts from bar, plate and forgings.

[wp-svg-icons icon=”calendar” wrap=”i”] Jul 15, 2008

[wp-svg-icons icon=”calendar” wrap=”i”] Jul 15, 2008

Royell has successfully installed the second phase of its new 5-axis Flexible Manufacturing System and once completed, this multi-million dollar investment will consist of four Machining Centers.

The completed configuration will be tied together by a 44 pallet system to stock and feed material 24 hours a day. This system is currently tooled and efficiently manufacturing wing rib components from aluminum plate.

[wp-svg-icons icon=”calendar” wrap=”i”] May 12, 2010

Although this press will be used primarily to support an interior stowage bin contract for Boeing, this program only requires a small percentage of the overall capacity. Royell has been adding to its non core activities to be able to offer its customers a more integrated support under one roof.

[wp-svg-icons icon=”calendar” wrap=”i”] Dec 20, 2010

[wp-svg-icons icon=”calendar” wrap=”i”] Dec 20, 2010

The Romer Absolute Arm 7-Axis “SI” series with integrated laser scanner delivers the convenience of a fully integrated 3D scanning solution. The scanner is permanently incorporated into the seventh axis, and weight counterbalance for ergonomics and ease of use. Single button automatic laser power control allows scanning of different surface types with over 8 feet of travel. No warm up time and no homing procedures means an operator can be up and scanning in just moment’s greatly increasing throughput in inspection.

[wp-svg-icons icon=”calendar” wrap=”i”] Sep 7, 2011

[wp-svg-icons icon=”calendar” wrap=”i”] Sep 7, 2011

Royell has successfully installed the third phase of it’s new 5-Axis Flexible Manufacturing System. The completed aluminum machining cell configuration will involve 4 machines tied together by a 44 pallet system that will feed material 24 hours a day with minimal supervision. This is a further step toward manufacturing automation that is gradually replacing the more conventional stand alone CNC machine

[wp-svg-icons icon=”calendar” wrap=”i”] Apr 6, 2012

[wp-svg-icons icon=”calendar” wrap=”i”] Apr 6, 2012

Royell has successfully installed the fourth and final phase of it’s new 5-Axis Flexible Manufacturing System. The completed aluminum machining cell configuration consists of 4 CNC machines tied together by a 44 pallet system that feed material 24 hours a day with minimal supervision. This is a further step toward manufacturing automation that is gradually replacing the more conventional stand alone CNC machines

[wp-svg-icons icon=”calendar” wrap=”i”] Oct 19, 2012

[wp-svg-icons icon=”calendar” wrap=”i”] Oct 19, 2012

The addition of a RoboDrill machining cell will enable parts to be conveyor fed both in and out of the machining station for unattended production. This is another step toward full automation of aircraft interiors parts manufacturing process that will enable Royell to drive down costs. Less handling and increasing throughput to help meet cost competitive requirements in this global market.