Royell has increased machining capacity within the Spares and Aircraft Modification manufacturing business unit with the addition of a new CNC machining center for volume part run sizes.

Royell has increased machining capacity within the Spares and Aircraft Modification manufacturing business unit with the addition of a new CNC machining center for volume part run sizes.

HAAS VF-4 vertical machining center with a 10,000 rpm 40 taper spindle and 50 x 20 x 25 inch table travel for aluminum work.

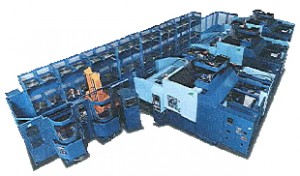

Also adding (2) HAAS VF-3YT vertical

machining centers with 7,500 rpm 50 taper spindles and 40 x 26 x 25 inch table travel. These are compact machines with good rigidity for hard metal machining. One machine will be used to support titanium parts roughing before finishing on our FMS whilst the other will machine complete complex titanium and inconel fittings. Both these machines are fitted with full 4 axis capability.