We achieved a perfect score on our recent ISO9000:2000 + AS9100B audit! This was somewhat of a surprise to us since our team that works continually developing better and leaner systems believe that the best is yet to come. Over the last ten years we have implemented a lean enterprise that includes leading edge technologies on the shop floor such as wireless communications to achieve work cell visibility and parts tracking. We have also developed our own software applications that not only manage these tasks but is also web based to help manage our supply chain from anywhere with an Internet connection.

We achieved a perfect score on our recent ISO9000:2000 + AS9100B audit! This was somewhat of a surprise to us since our team that works continually developing better and leaner systems believe that the best is yet to come. Over the last ten years we have implemented a lean enterprise that includes leading edge technologies on the shop floor such as wireless communications to achieve work cell visibility and parts tracking. We have also developed our own software applications that not only manage these tasks but is also web based to help manage our supply chain from anywhere with an Internet connection.

ROYELL OFFICES EXPANDED TO IMPROVE EMPLOYEE COMFORT AND WORK FLOW

To prepare the company for future growth and to maximize the flow pattern of administrative functionality our offices have been totally remodeled and expanded to 6000 sq ft.

To prepare the company for future growth and to maximize the flow pattern of administrative functionality our offices have been totally remodeled and expanded to 6000 sq ft.

The new look is an open concept design with many filing options removed from the work floor and wall mounted at convenient levels. The addition of two new conference rooms along with an updated training room complete with the latest digital equipment will support our long term plans. The final part of this 2006 expansion is an additional 2500 sq ft which will be the future center for our supply chain management activities.

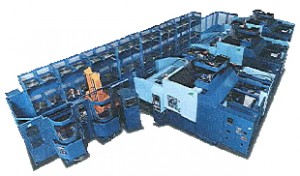

ROYELL INCREASES PRODUCTION AND SPARES MACHINING CAPACITY

Royell has increased machining capacity within the Spares and Aircraft Modification manufacturing business unit with the addition of a new CNC machining center for volume part run sizes.

Royell has increased machining capacity within the Spares and Aircraft Modification manufacturing business unit with the addition of a new CNC machining center for volume part run sizes.

HAAS VF-4 vertical machining center with a 10,000 rpm 40 taper spindle and 50 x 20 x 25 inch table travel for aluminum work.

Also adding (2) HAAS VF-3YT vertical

machining centers with 7,500 rpm 50 taper spindles and 40 x 26 x 25 inch table travel. These are compact machines with good rigidity for hard metal machining. One machine will be used to support titanium parts roughing before finishing on our FMS whilst the other will machine complete complex titanium and inconel fittings. Both these machines are fitted with full 4 axis capability.